Microinverters vs String Inverters | Comparison Between Them

With electricity prices continuing to rise across many parts of the country, solar power with the right inverter technology is an extremely smart long-term investment. However, the inverters that convert the panels’ DC output into usable AC power come in two main types – microinverters and string inverters.

Choosing the right option up front is crucial because inverters are expensive to replace later. Microinverters are best suited for small, complex, or shaded rooftops while string inverters perform well on larger, unshaded south-facing roofs.

Understanding these key distinctions will ensure your panels can operate at peak efficiency over their 25+ year lifetime. Read on to learn the detailed differences to determine which is better for your particular solar design.

How Do Solar Panel Inverters Work?

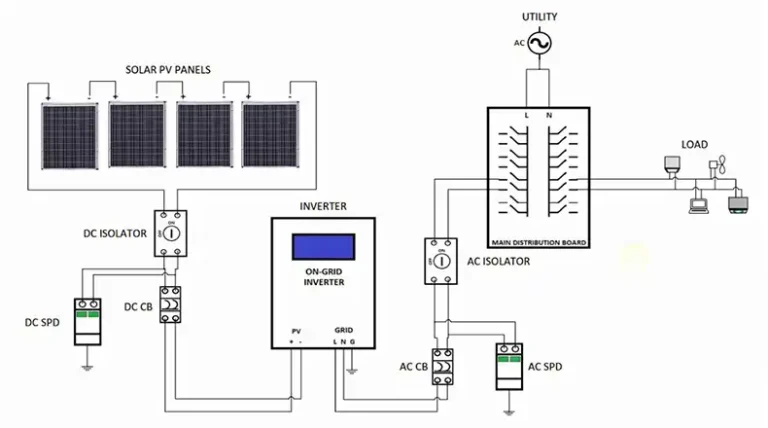

Before comparing microinverters vs string inverters, it’s important to understand what inverters do.

Solar panels produce direct current (DC) electricity when exposed to sunlight. This type of power is great for charging batteries but cannot directly power AC appliances in your home.

Inverters convert the panels’ DC output into alternating current (AC) that can be used to run lights, outlets, and devices. They also regulate and synchronize the voltage to match your building’s electrical system.

So in short, no inverter = no usable electricity from your solar array!

Microinverter vs String Inverter Overview

Broadly speaking, solar inverters fall into one of two categories:

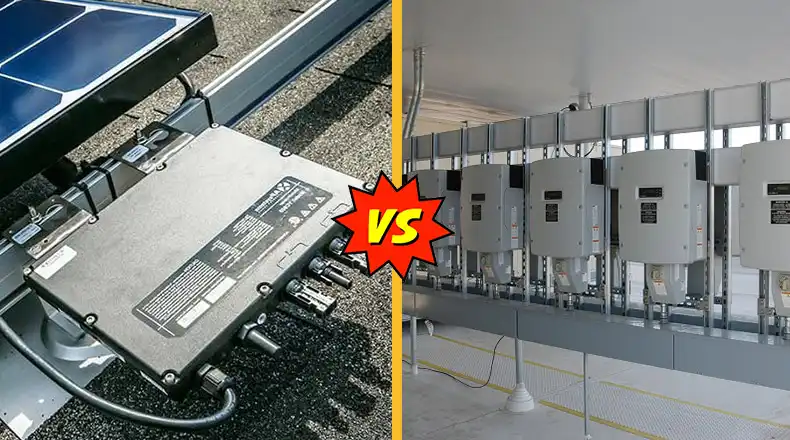

Microinverters – Small inverters mounted underneath each solar panel to convert DC to AC.

String Inverters – One larger inverter for many panels, converting aggregated DC power from panel “strings” into AC.

Let’s explore the unique pros and cons of each approach…

Microinverter Benefits

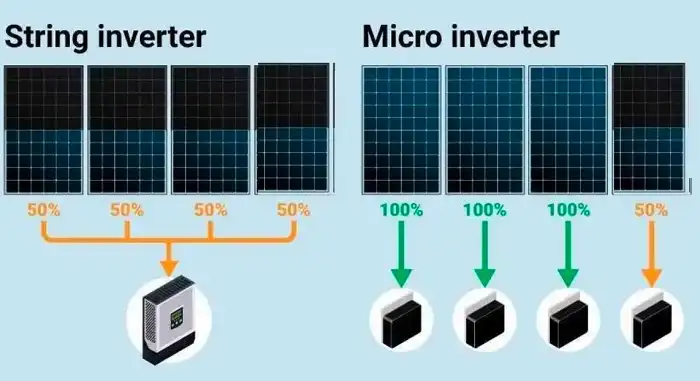

- Greater power optimization – as each panel has its own inverter, inter-row shading only affects the output of that panel rather than the whole array. Similarly, if one panel fails or collects dirt/debris, the rest of the system is unaffected.

- Flexible & modular – microinverters make it easy to add more panels incrementally over time. Their plug-and-play nature also simplifies initial installs and replacements.

- Real-time performance monitoring – microinverter systems provide panel-level data to pinpoint any developing faults or underperformance. Knowing your roof’s exact solar yield helps optimize its potential.

- Safer – with each panel operating at a low DC voltage, the risk of electrocution or arc faults is minimized.

String Inverter Benefits

- Cheaper – consolidating the inversion process into one powerful unit brings down costs, especially for large systems. String inverters are around $0.25 per Watt versus $0.45 to $0.60 per Watt for microinverter systems.

- Higher efficiency – string inverters can achieve peak efficiencies of around 98% by converting a greater volume of DC power at once. Microinverter peak efficiency currently tops out at 96% to 97%.

- Longer warranties – premium string inverters typically come with 10 to 20-year warranties covering faults and underperformance. Microinverter warranties range from 10 to 15 years.

- Simpler design – string systems have fewer connection points and wiring. The single inverter is also easier to access for service and replacement if needed.

Hopefully, this gives you a high-level sense of the comparative strengths and limitations of each approach. Next let’s get into more detail on how these differences apply specifically to small, average, and large solar arrays…

Microinverters vs String Inverters by System Size

The ideal type of solar inverter for your installation will depend largely on your array’s physical size and layout.

For Small Solar Arrays

Homes with tight roof spaces under 6 kW (18 panels) are often better served by microinverters. Their module-level MPPT tracking and power optimization ensure maximum production from constrained areas.

Limitations like inter-row shading, low light levels on certain sections, and panel mismatches have minimal impact on string designs. Microinverters also simplify incrementally adding more panels over time.

As small roofs see the greatest variance in sunlight exposure based on angles and surroundings, the panel-specific flexibility of microinverters is extremely useful. It allows for greater customization of orientations to maximize total energy yield.

The downside is microinverters do cost more upfront. However, the benefit of greater solar harvesting, especially in complex or suboptimal installations, tends to make that premium money well spent over the system’s lifetime.

For Average Solar Arrays

When moving into the 6 to 10 kW range (around 18 to 30 panels) suited to average-sized family homes, the decision between micro and string becomes less clear-cut. And there is a crossover point system-size-wise where string inverters gain substantial advantages.

Here string inverters can provide better economies of scale thanks to their consolidated design. By converting a greater volume of DC watts at once, conversion efficiencies reach upwards of 98% versus 95-97% with microinverters. So while less optimization occurs at the individual panel level, significantly higher aggregate efficiency balances this out on suitable roofs.

South-facing panels without major shading allow string inverters to perform extremely well for typical suburban constructions. Their lower costs also make these mid-range installs more affordable while still meeting 100% of most households’ power needs.

So for conventionally oriented arrays on 6 to 8 kW homes, string inverters with solar optimizers may provide the best performance-to-value ratio. If your site has higher shading/layout complexities though, microinverter optimization is worth the extra expense. Carefully consider the roof geometry and use case specifics before deciding.

For Large Solar Arrays

Once systems grow into the high kW ranges (25+ panels / 10 kW+ size), central string inverters tend to provide the best turnkey solution. Their ability to aggregate DC inputs from multiple large panel strings achieves economies of scale. This drives down kW costs while benefiting from very high (98%) peak efficiency at the utility-scale.

Larger open roof spaces also reduce external variability and inter-row shading. Making centralized equipment more viable since insolation is relatively consistent across many contiguous panels.

The superior warranties of heavy-duty string inverters also provide better long-term protection for expensive high kW installs and commercial solar projects. Outweighing benefits of micro-level optimization or incremental additions over time. 25-year manufacturer performance guarantees give helpful peace of mind.

So in summary – bigger unconstrained south-facing roofs allow string inverters to perform beautifully as a robust and affordable single-point AC conversion solution. Their cost-efficiency simply out-scales microinverters for large resi and commercial solar.

Solar Inverter Reliability & Lifespans

A key consideration beyond cost and efficiency is the usable lifespans these inverters provide. Replacing failed inverters causes major expense and disruption down the line.

Most solar panels have 25+ year rated lifespans and degrade performance minimally over decades. So having inverters designed for longevity matching the array is extremely important, especially for permanent mount structures.

Premium string inverters are built to withstand elements and come with 10 to 25-year warranties. Costing $0.15 to $0.65 per Watt. Budget units with shorter 5-year protections can be found for under $0.10 per watt, but longevity and performance are compromised.

Microinverters also provide 10 to 15-year manufacturer warranties, covering replacement if degradation exceeds guaranteed levels. However, their sophisticated electronics have more points of failure. Requiring $0.20 to $0.80 per Watt for long-lasting Enphase or SolarEdge models.

In real-world reliability tests across thousands of systems, both technologies see very low annual failure rates around 1-2% (for mature quality products). So neither has a distinct real-world advantage overall in robustness. But longer string inverter warranties do offer more future-proofing, especially on large projects.

For small installs under 5 kW though, microinverter warranties suffice and their panel-level redundancy minimizes system impacts of the odd failure. Keeping solar harvesting high across roofs with erratic shading/debris patterns.

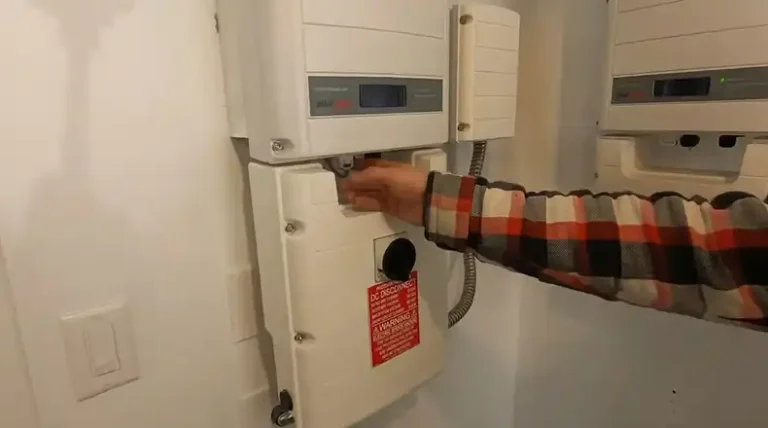

Comparing Ongoing Maintenance Requirements

While decent-quality inverters are generally quite reliable long-term, they still require periodic maintenance and the occasional service. Understanding these recurring costs and labor requirements also weighs into which technology works best for your needs.

Annual solar maintenance involves inspecting wiring connections, cleaning equipment, and spot-checking performance data. For string inverters, this takes 15 to 30 minutes per site visit to complete properly. Their centralized design allows for very efficient scheduled servicing.

For microinverter systems, comprehensive annual maintenance requires 45 minutes to an hour on average. Their distributed architecture has more connection points to inspect panel by panel across the roof. However next-gen models with wireless monitoring improve automation and reduce physical service needs.

Either technology may need mid-life firmware updates or fan replacements to ensure lasting high performance over decades of operation. Proactively replacing vulnerable components avoids major issues down the line. Which does require rolling service truck costs beyond basic labor.

So generally speaking, string inverters can be slightly more efficient to maintain but microinverters offer more software upgradeability and modular replaceability when issues eventually arise. Choose according to site accessibility, availability of service crews, and ability to finance future replacements if needed. Both options are broadly reasonable and with proper care keep O&M costs quite low.

The Core Differences Between Microinverters and String Inverters

Here is a comparison table summarizing the key differences between microinverters and string inverters:

| Feature | Microinverters | String Inverters |

| Cost | More expensive, $0.25 to $0.60 per watt | Less expensive, $0.15 to $0.25 per watt |

| Efficiency | Peak efficiency 96-97% | Higher peak efficiency up to 98% |

| Power Optimization | Module-level MPPT for better energy harvest | Single MPPT tracking for the whole system |

| Monitoring | Panel-level performance data | System-level data |

| Expandability | Easy to add more panels incrementally | Less flexible once installed |

| Reliability | 10 to 15-year warranties, redundant design | 10 to 25-year warranties available |

| Maintenance | More inspection points, 45-60 min annual service | Faster to service, 15-30 min annual check |

| Best For | Small complex roofs, incrementally growth | Larger simple layouts, affordability |

This summarizes how microinverters provide greater panel-specific optimization and flexibility while string inverters offer better economies of scale and peak efficiencies for larger systems. Consider your specific solar goals and site to determine the best option.

Microinverters Vs String Inverters

Here are the pros and cons of both microinverters and string inverters for solar installations:

Microinverter Pros

- Greater power optimization from panel-level MPPT

- Flexible & modular system design

- Easy to add more panels incrementally

- Safer low-voltage DC wiring

- Better performance in shaded conditions

- Real-time panel monitoring to catch issues

Microinverter Cons

- More expensive upfront equipment costs

- Slightly lower peak efficiency (~3% less)

- More physical connection points require maintenance

- Generally shorter 10-15 year warranties

String Inverter Pros

- Less expensive per watt for hardware

- Excellent peak efficiency up to 98%

- Longer manufacturer warranties are available

- Simplified system architecture

- Well suited for large open roof spaces

String Inverter Cons

- No panel-specific power tracking

- Large shaded areas drastically cut output

- Less flexible – difficult to add to linearly

- Higher DC voltages require safety precautions

- No module-level performance visibility

The main benefits and limitations of both true microinverter topology and centralized string inverter with “optimizer” hybrids balance pros from each side. Carefully weigh these factors against your installation’s unique site needs and conditions to choose the best inverter system design.

Which Solar Inverter is Best For My Home?

- Microinverters perform best on small complex installs with shading, multi-plane arrays, or obstructions. Their panel-specific optimization conquers many string technology limitations.

- For medium-sized south-facing roofs, string inverters provide superb economies of scale. Hitting peak efficiency upwards of 98% at lowest $/Watt costs. Making them a savvy choice when roof space accommodates their centralized design nicely.

- Large 10kw+ installs do best by combining high-power string inverters with solar optimizers for independent MPP tracking at cell levels. Creating an extremely robust peak efficiency design economical enough for residential scale.

- If incremental expansion may occur in the future, microinverters allow easy panel additions down the line. Whereas string systems are less configurable once commissioned.

- Harsher cold climates see bigger microinverter efficiency gains in low light and off-peak conditions. Their functionality shines brightly during dark winters!

Ultimately the site conditions and planned solar uses dictate which equipment allows your panels to operate most efficiently long-term for the budget available. Carefully weigh all the variables before committing to one approach over the other.

Conclusion

For small complex installs, microinverters provide unparalleled high-granularity optimization to maximize solar harvesting year-round. Mid-size arrays see excellent string inverter performance if site conditions accommodate their centralized topology. Large rooftops and solar carports are most economical with high-efficiency string inverters coupled with module-level power electronics for independent tracking. Always tailor solar designs around roof specifics and intended solar uses rather than assuming one inverter type suits all. Thanks for reading to the end and hopefully you now feel equipped to make sense of this critical solar decision. Please leave any remaining questions below!

Short Questions and Answers

Q: Why Are Microinverters More Expensive Than String Inverters?

A: Microinverters have sophisticated power electronics underneath each panel, so this distributed architecture requires more components. String inverters consolidate the inversion process into one centralized unit using cheaper high-volume parts.

Q: Can I Mix Microinverters And String Inverters On One Solar System?

A: It’s generally not recommended to combine microinverters and string inverters due to challenges synchronizing their separate AC outputs. Some exceptions exist but hybrid approaches often cause more issues than they solve.

Q: What Size Solar System Requires A Three-Phase Inverter?

A: Once solar arrays exceed 12 to 15 kW in capacity for a home, or 30 to 50 kW for a commercial site, three-phase string inverters are usually required by utilities so additional solar exports don’t overload neighborhood single-phase transformers.

Q: How Often Do Microinverters And String Inverters Need To Be Replaced?

A: With proper maintenance, top-tier string and microinverter models often operate reliably for 15 to 25 years. Their advanced electronics can outlive warranties but periodic component replacements may be needed over decades of use.

Q: Why Might I Choose Optimizers With String Inverters Instead Of Microinverters?

A: For very large rooftops or carports, solar optimizers provide similar panel-specific tracking to microinverters but at lower overall equipment costs. They balance per-panel data with shared string inversion hardware for affordable optimization.