[Troubleshooting] Solar Charge Controller No Load Output

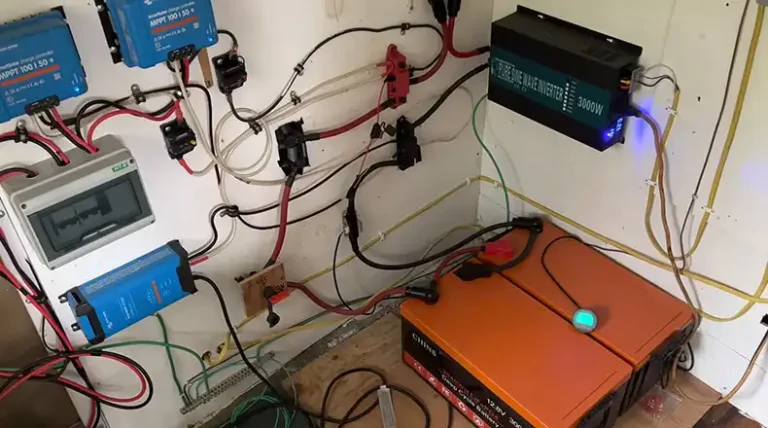

Solar charge controllers are essential devices that regulate power from solar panels into batteries. They prevent issues like overcharging using either PWM or MPPT to optimize the solar input voltage. Sometimes, controllers exhibit a higher or lower than expected “no load output” when not connected to a battery. This abnormal voltage could come from high heat, wiring problems, or failing components. Addressing no load issues early is key to avoiding permanent damage. Tracking no load output is vital for reliability.

The no load voltage shows how well a controller regulates solar panel power to batteries. The goal is stable, optimized output that efficiently charges without fluctuations that risk instability or safety. Monitoring no load output can uncover developing faults like worn parts before bigger failures happen. Preventative maintenance reduces costly repairs down the road.

Checking no load benchmarks periodically verifies charge controllers work properly for long periods as weather and parts age. Regular no load testing provides valuable insights that maintain functionality, extend operational lifetime, and protect investments in solar power equipment. Swiftly addressing abnormalities preserves system integrity over the years.

Main Functions of Solar Charge Controller No Load Output

At the heart of your solar power system, the charge controller acts as an observant guardian for your precious batteries. Its primary function is ensuring their well-being through a delicate balancing act. Think of it as a wise steward, carefully regulating the flow of electrical energy from your solar panels to prevent harmful extremes.

First and foremost, the controller serves as a shield against overcharging, which can cook a battery’s insides and shorten its lifespan. It monitors the voltage level and gracefully tapers off the charging current as the battery approaches its peak. Conversely, it also stands guard against over-discharging, which can leave your battery drained and lifeless. By setting a minimum voltage threshold, the controller disconnects any loads before they can sap the battery dry.

Furthermore, the controller acts as a silent sentry against short circuits, those pesky electrical gremlins that can cause catastrophic damage. By swiftly cutting off the current flow if it detects an unintended electrical path, the controller protects both your batteries and your equipment.

The solar charge controller plays a critical role in maintaining the delicate balance within your solar power system, ensuring your batteries live a long and healthy life, and fueling your energy needs for years to come.

Types of Charge Controllers

There are two main types of charge controllers: PWM (Pulse-Width Modulation) and MPPT (Maximum Power Point Tracking).

PWM controllers are simpler and more affordable, but they sacrifice some efficiency. They regulate the charge by rapidly switching the current on and off, essentially wasting some of the solar energy as heat.

MPPT controllers, on the other hand, are more sophisticated and can squeeze every drop of power out of your solar panels. They track the constantly changing voltage and current output of the panels, ensuring they operate at their most efficient point, which can translate to up to 30% more energy harvested compared to PWM controllers. While initially more expensive, MPPT controllers can be worthwhile if you have limited roof space or want to maximize your energy output.

No Load Output in Solar Charge Controllers

When we talk about “no load output” in a solar charge controller, it doesn’t quite mean the controller is completely powerless. Instead, it refers to the voltage measured at the output terminals when no battery is connected. Think of it as the controller’s potential, its readiness to deliver power, but without a recipient like a battery to actually receive it. This voltage is also known as the “open circuit voltage,” reflecting the electrical potential waiting to be tapped once a circuit is completed by connecting a battery.

To know about the no load output value can be helpful in troubleshooting situations where the controller isn’t functioning as expected. For example, if the no load output voltage falls significantly below the expected range, it could indicate a malfunction within the controller itself. Conversely, a sky-high no load output might signify an issue with the solar panels or wiring. Therefore, keeping an eye on this parameter, along with other key metrics like battery voltage and charge current, can provide valuable insights into the health and performance of your solar power system.

Factors Affecting No Load Output

To know about the no load output of a solar charge controller is like peering into the engine of your solar power system. It reveals the raw potential for power generation, before the battery steps in to act as the storage vessel. But this seemingly simple measurement is influenced by several factors, each playing a unique role in shaping the final voltage reading.

Solar Panel Voltage

First and foremost, the no load output is heavily dependent on the voltage produced by your solar panels. This voltage itself is determined by the number of cells connected in series and their individual characteristics. More cells strung together generally lead to a higher overall voltage, which translates to a higher no load output potential for the charge controller. Think of it as the raw power waiting to be harnessed.

Temperature

Temperature, both of the environment and the charge controller itself, plays a subtle yet crucial role in the no load output equation. While higher ambient temperatures might seem favorable for solar energy production, they can actually lead to reduced efficiency within the charge controller’s internal circuitry. This can indirectly affect the no load output voltage, causing it to dip slightly compared to cooler conditions. However, modern controllers often employ thermal management techniques to mitigate this effect.

Charge Controller Topology

The type of charge controller you use also significantly impacts the no load output. Two main types dominate the market: PWM (Pulse Width Modulation) and MPPT (Maximum Power Point Tracking). While both ultimately deliver power to the battery, they handle the incoming solar voltage in fundamentally different ways.

| Criteria | PWM Controllers | MPPT Controllers |

| Efficiency | Lower | Higher, especially in variable conditions |

| Cost | Lower | Higher initial cost, potential for long-term savings |

| Suitable Applications | Small-scale, consistent sunlight | Large-scale, variable weather conditions |

| Voltage Matching | Less effective in handling voltage variations | More effective in handling voltage variations |

| Complexity | Simpler design and operation | More complex design and operation |

PWM Controllers

These simpler and more affordable models essentially act like switches, rapidly turning the current on and off to regulate the flow to the battery. However, this “chopping” approach can result in some energy being lost as heat, leading to a slightly lower no load output voltage compared to the raw solar input.

MPPT Controllers

These sophisticated alternatives take a more nuanced approach. They actively track the constantly changing voltage and current output of the solar panels, ensuring they operate at their most efficient “sweet spot” regardless of external factors. This allows MPPT controllers to potentially boost the no load output voltage beyond the raw solar input, squeezing every drop of power from your panels.

No Load Output

Monitoring the no load output can be a valuable tool for assessing your solar power system’s performance and health. By establishing a baseline no load output voltage under optimal conditions, you can track any changes over time. A sudden drop could indicate issues with the controller’s internal circuitry, while a persistent low voltage might point towards problems with the solar panels or wiring. Regular checks can help you catch potential issues early on, ensuring your system continues to generate power at its peak potential.

The world of solar energy can be fascinating, and studying the topic deeply into its difficulties can unlock a whole new level of dealing and appreciation for your power system.

Troubleshooting No Load Output Issues

Facing a no load output situation with your solar charge controller can be frustrating, but don’t let it dim your sunny outlook! Let’s discuss the problems behind this issue and equip you with a step-by-step approach to diagnose and address the problem.

A. Common Problems and Causes

1. Faulty Wiring or Connections: Loose or corroded connections between the solar panels, controller, and battery can disrupt the flow of electricity, leading to a no load output. Think of it as a broken link in the chain of power transmission.

2. Controller Configuration Errors: Improper settings or misconfigured parameters within the controller can also hinder its ability to function properly.

3. Component Malfunctions: Internal failures within the controller or other components like the solar panels themselves can be behind the no load output issue. Picture a faulty spark plug in your car engine – it can prevent the engine from even attempting to start.

B. Step-by-Step Diagnosis Process

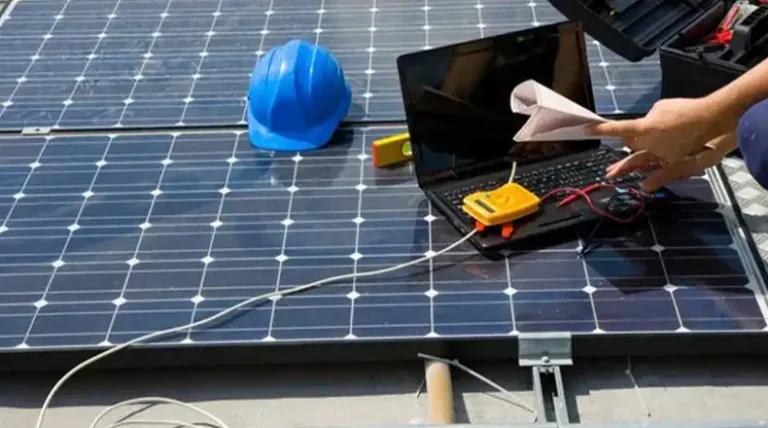

Step-1. Visual Inspection: Start with a thorough visual inspection of the entire system. Check for loose or corroded connections, damaged wires, or any visible signs of physical damage to the controller or panels. A quick visual sweep can often reveal obvious problems.

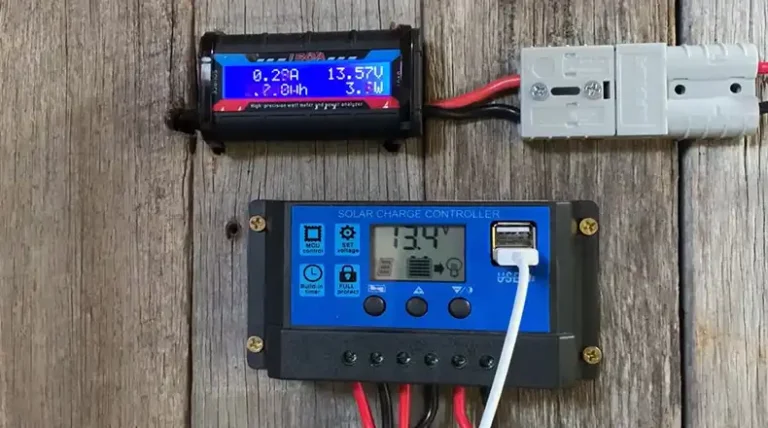

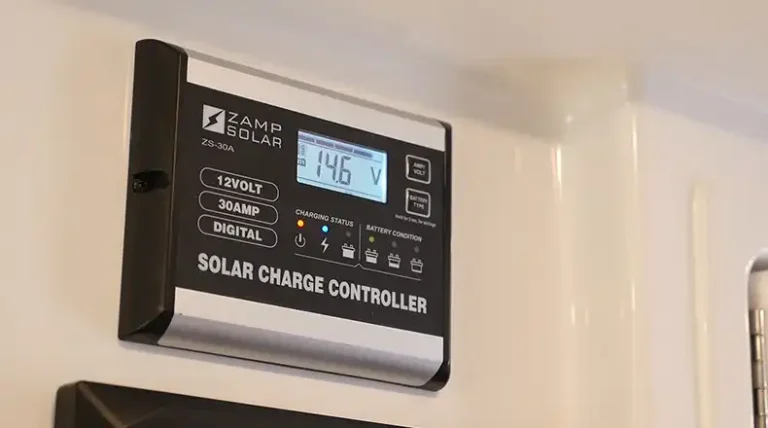

Step-2. Voltage and Current Testing: Equipped with a multimeter, take voltage and current measurements at various points in the system, such as the solar panel output, controller input and output terminals, and battery voltage. Comparing these readings with expected values based on your system specifications can help pinpoint where the issue lies. Think of it as taking the system’s vital signs to diagnose the problem.

Step-3. Using Monitoring Tools: Many modern solar charge controllers come equipped with built-in monitoring features or connect to external monitoring systems. These can provide valuable insights into system performance, including historical data and error logs.

By systematically following these steps and interpreting the collected data, you can effectively diagnose the cause of your no load output problem. Once you identify the problem, you can take appropriate action, which may involve tightening connections, reconfiguring settings, or replacing faulty components.

Pros and Cons of Solar Charge Controller No Load Output

While “no load output” from a solar charge controller seems like a negative situation, it actually has both pros and cons that need to be considered in context. Here’s a breakdown:

Pros

1. Safety Feature: When no battery is connected, the controller doesn’t generate any voltage, preventing dangerous sparking or electrical shocks. This protects both the system and anyone working on it.

2. Easy Troubleshooting: Measuring the no-load output voltage provides a valuable diagnostic tool. By comparing it to known values for your system, you can easily identify issues like faulty wiring, controller malfunctions, or solar panel problems.

3. System Check: If you’re installing or maintaining your system, checking the no-load output allows you to verify the functionality of the controller and solar panels before connecting the battery. This can prevent potential damage from incorrect connections or settings.

Cons

1. Power Loss: In systems where energy efficiency is critical, any power not used is lost. While minimal, the no-load output voltage represents potential energy that could be stored in the battery.

2. Limited Information: While helpful for troubleshooting, the no-load output doesn’t tell the whole story of the controller’s performance. Understanding its behavior under actual load is crucial for optimizing your system’s efficiency.

3. Misleading Readings: External factors like temperature and sunlight can influence the no-load output voltage. Therefore, relying solely on this value for diagnostics without considering other factors can lead to misinterpretations.

Your Questions Answered

Q1. Can I run my appliances directly from the controller’s no load output?

No, the no load output voltage typically isn’t high enough to power most appliances directly. Even if it appears sufficient, bypassing the battery can damage both the appliances and the controller due to unstable voltage fluctuations. Remember, the battery acts as a stable reservoir for storing and delivering the solar energy.

Q2. Is it okay for the no load output voltage to change throughout the day?

Yes, slight variations in the no load output voltage are normal. Temperature, sunlight intensity, and even cloud cover can influence the voltage produced by the solar panels, which in turn affects the no load output reading. However, significant or sudden drops might indicate issues with the controller or panels, warranting further investigation.

Q3. My controller displays “No Load,” but my battery isn’t charging. What’s wrong?

This could be due to various factors. Low battery voltage might trigger the controller’s low voltage disconnect feature, preventing charging to protect the battery. Faulty wiring, incorrect controller settings, or even problems with the panels themselves can also be culprits. Check your battery voltage, connections, and controller settings first. If unsure, consulting a qualified solar technician is recommended.

Q4. Should I monitor the no load output regularly?

While not required for day-to-day operation, periodically checking the no load output can be a valuable preventative measure. By establishing a baseline voltage under optimal conditions, you can easily identify any significant changes over time. This can help you catch potential issues with the controller, panels, or wiring before they cause major problems. Remember, early detection leads to easier and faster solutions.

Summing Up

Carefully monitoring no load output voltages is crucial for maintaining solar charge controller health over decades of operation. Regular no load testing provides critical data to catch issues early before small problems cause system failures. With vigilant oversight to ensure optimal controller performance, solar power systems can reliably and efficiently convert sunlight into usable energy for the long haul.