Half-cut Solar Cells – A Revolution in Solar Technology

The solar PV market has witnessed tremendous growth, with solar energy capacity increasing over 200 times between 2000-2019. However, as solar installations multiply, efficient utilization of space and enhancement of power generation capacity remain key priorities. That’s where the half-cut solar cell technology comes into play.

Half-cut solar cell modules are set to provide a solution through perceptible performance benefits like lower temperature coefficients, reduced resistive losses, and better shading response. With their ability to generate more power per square meter, half-cut cells facilitate space optimization. Their higher efficiency can also translate into lowered Balance of System (BOS) costs owing to reduced space requirements.

Let’s explore more about half-cut solar cells including what they are, how they work, what’s the differences, their advantages and disadvantages, and much more in this article below!

What are Half-cut Solar Cells?

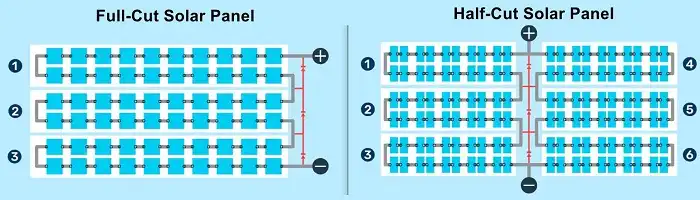

Half-cut cells are PV cells that have been cut into two halves before being assembled into a solar module. Conventional solar panels use full-size monocrystalline silicon cells of dimensions 156mm x 156mm in a 60-cell format. Half-cut modules utilize 120 cells of dimensions 156mm x 78mm, which are essentially halves of the full cells.

The conversion efficiency of a solar module depends on the amount of energy extracted from sunlight versus the amount of incident irradiance. By reducing the resistive losses and temperature coefficients, half-cells help minimize energy losses, enabling higher efficiency.

Evolution of Half-cut Cell Technology

The half-cut design was first introduced around 2010 as an innovation to mitigate the effects of cell cracks and hotspots in solar modules. As their benefits became more apparent, the use of half-cut cells gained further impetus through extensive research over the next decade.

Today, they represent the most efficient PV module design and are expected to be the standard product feature by 2025. Let’s see how it works.

How Do Half-cut Solar Panels Work?

Half-cut modules comprise solar cells of dimensions 156mm x 78mm, which are essentially two equal halves of the 156mm full-size cells. Consequently, a regular 60-cell module transforms into a 120 half-cut cell module. The smaller cells are symmetrically arranged and interconnected by thin strips of conducting ribbon.

The key differences in working arise due to –

- More number of cells per module

- Introduction of cell gaps across the module

- Lesser area and current per cell

Conventionally, solar modules use full cells with three thin busbars for interconnection. In contrast, half-cut cell modules utilize six thinner busbars per cell.

Let’s analyze how these structural changes translate into enhanced performance for half-cut modules:

Cell Temperature Regulation

During operation, solar cell temperature increases proportionally to the current density and resistive losses. By reducing cell width to half, half-cut cells lower current density, resistive heat dissipation, and operating temperature considerably.

The cell gap between halves facilitates better airflow and cooling while enhancing rear-surface reflection onto neighboring cells. This preserves higher voltage output.

Lower Resistive Losses

In full-size cells, increased charge carrier flow across greater distances generates more resistive heating. This resistive loss causes efficiency reduction.

In half cells, current traversing cell width reduces to half, minimizing resistive losses substantially. Thus, resistive heat dissipation lowers by 75%!

Improved Mismatch Tolerance

Electrical mismatch losses occur when individual cells have different operating characteristics. As cell segments reduce to half, mismatch tolerance improves significantly through a more uniform voltage profile.

Enhanced Shading Tolerance

With 120 cell configurations, the number of bypass diodes doubles. This offers redundant current paths under shaded conditions by allowing current to flow through alternate cell strings.

Thus, the unique changes in the cell structure and connections enable half-cut modules to outperform their full-cell counterparts! Now, let us explore the manufacturing process for half-cut modules.

Manufacturing Process of Half-cut Solar Panels

Similar to conventional solar panels, manufacturing half-cut PV modules involves quartz reduction, ingot casting, wafering, diffusion, anti-reflective coating, metallization, and interconnect. However, additional steps like laser cutting and cell stringing with more number of busbars need to be introduced.

Let’s understand the critical stages:

1. Cell Slicing

The bulk silicon wafer with PN junction formed is laser cut into two equal halves of dimensions 156mm x 78mm rather than using 156mm full cells. Laser cutting achieves precise dimensional control while minimizing cracks.

2. Cell Processing

The rounded edges of half-cells are trimmed before cleaning and AR coating processes. Half-cells undergo expanded busbar printing for redundancy through six busbars instead of three in full cells.

3. Stringing

A key step where 120 half-cells are reconfigured into cell strings by soldering them in series. Thin conducting tabs provide interconnected cell strings for desired voltage output before lamination.

4. Layup and Lamination

Half-cut cell strings aligned between encapsulant layers and rear back sheet are vacuum-pressed under elevated temperature for encapsulated string consolidation.

5. Framing and Junction Box

The laminated PV module is fit into the aluminum frame before attaching the junction box. Wire interconnects from the junction box carry output power.

While cell slicing and stringing are additional steps, utilizing half-cells enables manufacturing high-efficiency modules. Now, let’s identify the difference between half-cut cells and standard full-cut cells.

Differences Between Half-cut and Full-cut Solar Panels

Here are the key differences between half-cut and full-cut solar panels:

| Parameter | Full-cut Solar Panel | Half-cut Solar Panel |

| Cell Dimensions | 156 mm x 156 mm | 156 mm x 78 mm |

| No. of Cells | 60 | 120 |

| Cell Area | 243 cm^2 | 121.5 cm^2 |

| Busbars per Cell | 3 | 6 |

| Module Efficiency | Up to 20.5% | Up to 21.3% |

| Temperature Coefficient | -0.35 %/°C | -0.32 %/°C |

| Resistive Power Loss | Higher | Lower by 75% |

| Shading Tolerance | Moderate | Very Good |

| Annual Energy Yield | Reference | > 5% Higher |

| LCOE | Reference | 4-9% Lower |

| Manufacturing Complexity | Simple | Complex |

| Cost per Watt | Lower | 5-10% Higher |

This summary comparison highlights why the efficiency, performance, and economic benefits of half-cut modules outweigh the incremental module costs for most applications. With their long-term value proposition, half-cut cell solar panels present a superior technology option for the future.

Let’s further assess the costs involved.

Cost Analysis of Half-cut vs Full-cut Solar Panels

For manufacturers, migrating from full-cut to half-cut cell technology requires significant investments in specialized laser-cutting equipment and automation for stringing 120 cells per module. The additional processing steps also impact costs marginally.

However, as the learning curve matures and production scales up, costs are likely to even out. Manufacturers believe the capex payback from superior half-cut module efficiency and energy yield can be realized within two years.

For utility-scale solar projects, developers need to assess tradeoffs between higher upfront module costs versus the benefits of better LCOE from increased annual energy generation. Half-cut gains can achieve LCOE savings between 4-9% as compared to polycrystalline panels.

Comparative analysis indicates that over 25 25-year lifespan, capex for half-cut modules at 4% higher costs can realize 6-8% superior LCOE due to their better yields. Thus, long-term returns indicate an attractive proposition.

As manufacturing innovations aim for further cost parity, half-cut cell benefits position them as premium efficient modules for the future. Now, let’s examine why half-cut modules outperform their full-cell counterparts.

Benefits and Drawbacks of Half-Cut Solar Cells

Here are the benefits and drawbacks of using half-cut solar cells are explained:

Benefits of Half-cut Solar Cells

1. Higher Efficiency

By reducing current flow through each cell, half-cut cells can minimize resistive losses which directly enhances module efficiency. Half-cut modules using 166mm cells can achieve efficiency gains of 1-3% over full-cell modules.

2. Lower Temperature Coefficient

In half-cut cells, the operating temperature is reduced by 5-10°C through better heat dissipation across the new cell gaps. This preserves higher voltages, enhancing performance.

3. Reduced Cell to Module (CTM) Losses

Introducing gaps between cells causes the current to undergo multiple parallel connections before module interconnection. This minimizes mismatch losses, enabling higher output.

4. Better Shading Tolerance

With double the number of bypass diodes, half-cut modules experience lower shading losses and can handle shaded conditions better during early mornings or late evenings.

5. Aesthetic Appeal

Half-cut cell edges across the front module face create a visual appeal through an elegant black border design.

6. Optimized Space Usage

The roughly 5-7% greater power generation facilitates setting up more capacity in space-constrained solar projects to better optimize available areas.

7. Lower LCOE

High efficiency and better temperature coefficient lead to increased energy yield by 5-10% for the same system size. Thus, the levelized cost of solar electricity can be reduced by 5-10%.

8. Improved Reliability

With lesser current per cell string, thermal stress is reduced, enhancing PV module reliability. Further, smaller cells are less prone to microcracks.

The myriad technological and performance benefits offered by half-cut cells culminate into lower LCOE, making solar power more cost-competitive.

Drawbacks of Half-cut Solar Cells

While half-cut modules offer significant efficiency and performance benefits, there are some downsides to consider:

- Higher Upfront Costs

Manufacturing half-cut cells requires additional processing like cell slicing, stringing, more busbars, etc. This leads to marginally higher production costs, increasing the initial purchase price by 5-10% over conventional panels.

- Increased Complexity

Introducing smaller cells and more interconnects increases the complexity of half-cut modules. This demands greater quality control and automation during production while requiring improved mounting structures.

- Efficiency Losses at Higher Temperatures

As operating temperature rises beyond 25°C, half-cut cells experience a slightly faster drop in efficiency owing to their advanced cell technology.

- Technology Lock-in

Committing to a newer technology where long-term field reliability and degradation data are still accumulating carries some inherent technology adoption risks.

Thus, these limitations merit consideration for temperate climatic conditions where cell temperature is likely to exceed 25°C consistently. However, continuing innovation is helping address these challenges too. Next, let’s assess some remarkable solar projects utilizing half-cut cell technology.

Notable Solar Projects Using Half-cut PV Modules

Several prominent solar developers worldwide have recognized the long-term value proposition of deploying high-efficiency half-cut cells. Some stellar projects powered by half-cut modules are:

- Rabigh Project (Saudi Arabia)

Operational since April 2020, phase 3 of this solar park comprised 1.8 million Hanwha Qcells half-cut cell modules amounting to 600 MW capacity.

- Benban Solar Park (Egypt)

As Africa’s largest solar park spread over a 37 km2 area, Benban has used extensive 500W half-cut cell bifacial PV modules supplied by JinkoSolar to generate 1.65 GW capacity since 2019.

- Dau Tieng Solar Farm (Vietnam)

A prominent renewable project commissioned in mid-2021, the Dau Tieng solar farm employs half-cut mono PERC modules supplied by JA Solar to install 335 MW capacity.

These landmark solar energy projects demonstrate that half-cut modules are undoubtedly the premium product trending in the PV industry today owing to their exceptional field performance and returns.

Future Perspectives of Half-cut Solar Cells

Half-cut cell technology has cemented its position as the breakthrough advancement driving higher solar module efficiency. Today, more than 17 companies worldwide offer half-cut cell panels, indicating their growing adoption.

By 2025, over 80% of Asian module manufacturing capacity is forecasted to shift towards half-cut product lines through fresh capital investments. Dominant Chinese PV manufacturers like Jinko Solar and Trina Solar acquiring market share substantiate this projection.

Furthermore, half-cell innovation synergizing with advanced concepts like multi-busbars, shingled cells, heterojunction technology, and bifacial functionality are set to push efficiency frontiers even higher!

Continued research and product development equip half-cut modules to remain at the helm of cutting-edge solar technology while spurring mainstream solar adoption.

Summary

Half-cut cells represent the most efficient solar technology today through higher yields over 25+ years. Their segmentized structure offers multiple performance benefits like lower temperature coefficient and resistive losses that cascade into substantially higher efficiency. Despite slightly higher upfront costs, half-cut solar promises a better return on investment through increased annual energy output per system area. With solar rooftops and plants rapidly adopting this premium product, half-cut modules are undoubtedly positioned as the solar panel trend of the present and next decade. I hope this quick read offered a useful peek into this breakthrough PV innovation! Please share your feedback or queries below. Thank you!

Other Related Questions

Q1. How Much More Efficient Is A Half-Cut Solar Panel?

A1. Half-cut solar modules can achieve 1-3% higher module efficiency over conventional full-cell panels of the same capacity. In terms of energy yield, field data indicates 5-10% higher annual energy output over 25 years.

Q2. Why Are Half-Cut Solar Panels Better?

A2. Half-cut modules offer perceptible benefits like lower temperature coefficients, reduced resistive losses, superior shading tolerance, and optimized space usage. Combined with better efficiency, these value propositions enable half-cut solar technology to deliver 5-10% better LCOE.

Q3. Are Half-Cut Solar Panels Worth It?

A3. Although half-cut panels entail slightly higher initial purchase costs, their exceptional efficiency, energy yield, and longevity benefits outweigh the incremental capex substantially. Over 25 25-year lifespan, they deliver considerably higher return on investment along with lowered LCOE.

Q4. What Is The Difference Between a Cell and Half Cell Panel?

A4. Key differences include – half-cut cells being smaller segments (156mm x 78mm vs 156mm x 156mm), enabling 120 cells per panel (vs 60), with cell gaps for better cooling. Due to lower current per cell, resistive losses are reduced, improving efficiency.

Q5. Which Company Has the Best Half-Cut Panel?

A5. Some of the best half-cut solar panels supplied globally come from Jinko Solar, Canadian Solar, Trina Solar, Qcells, JA Solar, and Risen Energy. Using advanced passivated emitter rear cell (PERC) technology, these half-cut modules achieve 19-21% efficiency ranges with tremendous reliability.