Wire Won’t Fit In Charge Controller | Reasons & Solutions

The charge controller is a vital component of a solar power system, responsible for regulating the flow of electricity from the solar panels to the batteries. However, one common challenge faced by solar panel owners is the frustrating issue of wires not fitting properly into the charge controller.

But do you know why your wires may not fit in the charge controller? It’s simply because charge controllers are designed to accept a specific size of wires. If the wires are too thick or too thin, they will not fit.

Fear not, dear reader, as I’m here to help you fix this issue. I’ll help you identify the root causes, explore effective troubleshooting techniques, and provide practical solutions to ensure your solar power system operates at peak efficiency.

Why The Wire May Not Fit In Charge Controller

The charge controller plays a pivotal role in this intricate network, acting as a gatekeeper between the solar panels and the batteries. When the wires connecting these components fail to fit snugly into the charge controller, it can lead to a cascade of issues that compromise the system’s performance.

One of the primary reasons for this problem is the mismatch between wire gauge and terminal size. Wire gauge refers to the thickness of the wire, with lower gauge numbers indicating thicker wires capable of carrying higher currents. Charge controllers are designed to accommodate specific wire gauges, and using wires that are too thick or too thin can result in a poor fit, potentially causing electrical arcing, overheating, or even fire hazards.

Another contributing factor could be the type of wire termination used. Charge controllers typically have designated terminals for different wire connections, such as solar panel inputs, battery outputs, and ground connections. Improper termination techniques, like inadequate stripping or poorly crimped lugs, can prevent the wires from fitting securely into the terminals.

Additionally, physical damage or corrosion on the charge controller terminals or wire ends can impede proper wire fitment. Over time, exposure to environmental factors like moisture, heat, or debris can degrade the components, making it challenging to achieve a tight connection.

Troubleshooting Steps for Wire and Charge Controller Terminal Mismatch Issue

Before attempting any repairs or modifications, it’s crucial to follow proper safety protocols. Disconnect the solar power system from all energy sources, including solar panels and batteries, to avoid potential electrical shocks or short circuits.

Step 1- Inspect the Wire Gauge: Carefully examine the wires and compare their gauge to the recommended specifications in the charge controller’s manual. If the wire gauge is incorrect, you’ll need to replace the wires with the appropriate size.

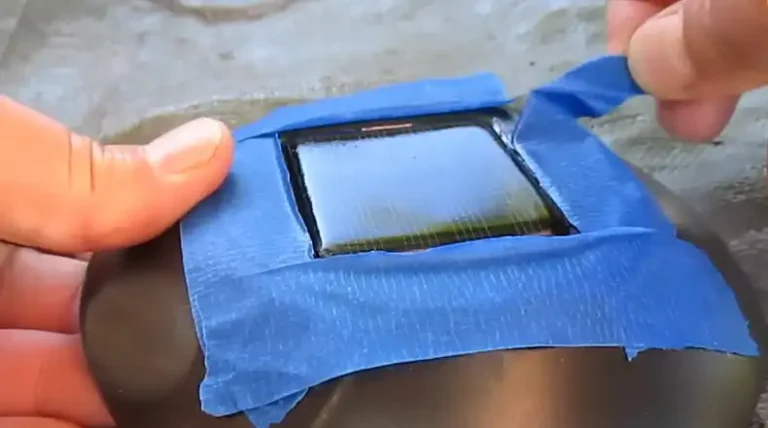

Step 2- Check Wire Terminations: Inspect the wire terminations, such as lugs or ferrules, for any signs of damage or improper crimping. If necessary, re-terminate the wires using the correct techniques and tools.

Step 3- Clean the Terminals: Use a wire brush or emery cloth to gently remove any corrosion or debris from the charge controller terminals and wire ends. Ensure to clean both surfaces thoroughly to promote better electrical contact.

Step 4- Adjust Terminal Tension: Some charge controllers feature adjustable terminal screws or clamping mechanisms. Consult the manufacturer’s instructions and carefully adjust the tension to achieve a snug fit without over-tightening, which could damage the components.

Step 5- Inspect for Physical Damage: Carefully examine the charge controller and wires for any signs of physical damage, such as cracks, dents, or bent terminals. If significant damage is present, it may be necessary to replace the affected components.

Note: If you’ve exhausted all troubleshooting options and still can’t resolve the issue, it may be wise to consult a professional solar technician or electrician. They possess the expertise and specialized tools necessary to diagnose and rectify complex wiring problems safely and effectively.

Conclusion

All the possible reasons for the wires not fitting in the charge controller issue and their solutions have been discussed in the above section. By following the troubleshooting steps outlined in this guide and exploring potential solutions, you can overcome this common challenge and enjoy uninterrupted solar energy harvesting. If you have any further questions or need additional clarification, please feel free to leave a comment in the section below. I’d be more than happy to assist you further. Wishing you the best of luck in resolving this issue and maximizing the benefits of your solar power investment!

FAQs

What Could Happen If I Force the Wire Into the Charge Controller?

Forcing a wire that doesn’t fit properly into the charge controller could lead to severe consequences. It might cause damage to the terminal, creating a loose connection that could overheat and potentially start a fire. Additionally, it could compromise the integrity of the electrical system, leading to power losses and inefficient energy transfer.

Can I Use Wire Nuts Instead of Proper Terminations?

Wire nuts are not recommended for use in solar power systems, as they are not designed to withstand the constant vibrations and environmental conditions that solar installations are exposed to. Proper wire terminations, such as lugs or ferrules, provide a secure and long-lasting connection that can handle the demands of a solar power system.

How Often Should I Inspect the Wiring and Connections?

It’s generally recommended to inspect the wiring and connections of your solar power system at least once a year, or more frequently if you live in an area with extreme weather conditions or have experienced any recent electrical issues. Regular inspections can help identify potential problems before they escalate and ensure the safe and efficient operation of your system.

Can I Mix Different Wire Gauges in My Solar Power System?

Mixing different wire gauges in a solar power system is not recommended. Each component, such as the charge controller, inverter, and battery bank, is designed to work with specific wire gauges based on the voltage and current requirements. Using mismatched wire gauges can lead to voltage drops, power losses, and potential safety hazards.

What Are the Signs That My Charge Controller Needs Replacement?

Some signs that your charge controller may need replacement include frequent tripping or shutdowns, inconsistent battery charging, visible damage or corrosion on the terminals, and an inability to properly regulate the flow of electricity from the solar panels to the batteries. If you notice any of these issues, it’s best to consult a professional solar technician to assess the condition of your charge controller.

![Do Solar Roof Vents Work At Night [Answerd]](https://www.itekenergy.com/wp-content/uploads/2024/04/Do-Solar-Roof-Vents-Work-At-Night-768x428.webp)

![[Explored] Why Is There an OnOff Switch on Solar Lights?](https://www.itekenergy.com/wp-content/uploads/2023/07/Why-Is-There-an-OnOff-Switch-on-Solar-Lights-768x428.webp)

![[Explained] What Size Fuse for 3000 Watt Amp for Solar Inverter?](https://www.itekenergy.com/wp-content/uploads/2023/08/What-Size-Fuse-for-3000-Watt-Amp-for-Solar-Inverter-768x428.webp)